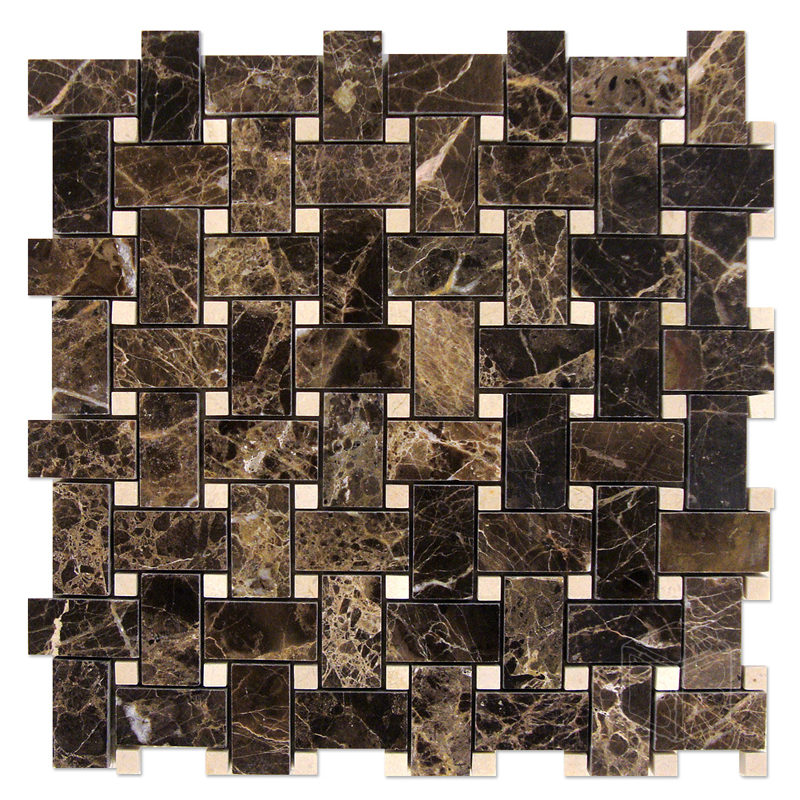

Stone mosaic is widely used, hotels, home improvement can come in handy. Stone mosaic mainly marble mosaic, granite mosaic, jade mosaic, travertine mosaic, shaped mosaic, artistic waist mosaic and other products.

Stone mosaic mosaic production is mainly stone parquet block processing, parquet of raw materials mainly from the large stone processing plant in the cutting board cut the remaining corner material, preferably below 1cm sheet cutting the remaining edge material, stone Of the variety, color is more the better.

Most mosaic parquet is the use of matte or rough surface, but also the use of polished surface of the stone, the size is generally 2-3cm square, according to the need to choose a larger surface size. For low-volume production or production of mosaic stone mosaic products, you can use a diamond saw blade with a small desktop cutting mosaic mosaic cut, you can also use the upper and lower cutting with a small hydraulic cutting machine mosaic mosaic block processing, stone processing Granite mosaic, only one piece of the cut; if you want to mass production rules of the shape of marble mosaic blocks, the use of bridge bridge cutting machine is feasible, can be a number of plates stacked together, with a special fixture fixed , One can cut a few pieces of parquet blocks, processing and high efficiency.

Polished surface mosaic blocks can be cut directly from the edge of the light board to obtain. While the matt or matte side of the parquet blocks need to be rough surface treatment. First, 1-2cm thick, different colors of discarded sheet corners cut into squares, rectangles, triangles, rhombuses, or other regular parquet blocks that can be used as the basic shape of the parquet, into the drum. When the drum rotation, the friction between the plates, and ultimately the formation of regular shape, smooth corners, the surface matte, the same degree of wear and tear of the surface of parquet blocks.

Stone mosaic pattern mosaic pattern laying there are three ways, one in the overall plate adhesion, splicing pattern method, also called direct assembly method. In addition, there are two kinds of rough surface mosaic pattern of stone mosaic laying method, one back paper method, similar to the glass mosaic, first paste a good pattern to paste kraft paper online, with concrete directly to the mounting surface , After curing, remove the paper can be; the other is the bracket method, according to the design pattern in advance, the production of some ABS plastic bracket, each piece of rough stone corresponding to a bracket, bracket with screws fixed to the mounting surface , And then use the adhesive to stuck to the stone, the same can form a variety of graphic beauty, antique stone mosaic effect, the construction is very convenient. Back paper method is simple to install, due to the stone manufacturers, the pattern has been designed in advance, so the composition of the screen a single, rigid, lost artistic creativity, but very suitable for factory standardization, mass production mode. Although the bracket method of teaching to teach complex, but by the installer in accordance with the pre-designed pattern, shape to the composition, leaving the installer to play the imagination of the larger space.

Shenzhen Venice Hotel is a mosaic parquet kingdom, the Venice hotel restaurant ground, all with stone mosaic pavement. If you look inadvertently, it is like a good soft carpet weaving. Simple but without losing the artistic appreciation of the value of color, although the color is only black and white yellow is not monotonous, although the shape is usually square or rectangular in the constant repetition of the United States and Founder show strength.

English

English